Application Overview

The cyclone fluidized bed granulation and coating machine is a fluidized bed with a blade structure, and the blades are inclined to a certain degree, allowing the airflow to pass through the gaps of the blades, forming a strong circulating airflow, causing the materials to move in a vortex like orderly manner. At the same time, the pneumatic nozzle installed on the side wall sprays the adhesive or coating liquid into the vortex like material layer, thereby turning the powder into particles or obtaining a continuous and uniform coating film. It is widely used in powder granulation and film, enteric coating, slow release coating of powder, particles, and pellets, as well as coating of various materials such as odor masking, moisture-proof, waterproof, coloring, thermal insulation, and isolation.

Equipment characteristics

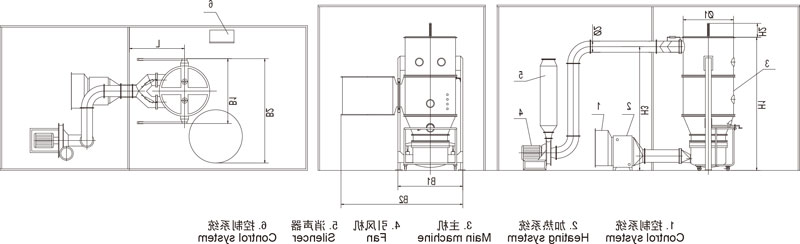

★Swirl driven air distributor ensures orderly movement of materials.★Swirl fluidization overcomes the phenomenon of channel flow and dead corners.★The prepared particles are porous, instant, with high sphericity, good surface glossiness, strong density, and are not easily broken.★Materials with poor moisture absorption and fluidity can also be made into qualified particles.Outline Dimensional Drawing

| Project specifications | 0.5 | 5 | 10 | 15 | 30 | 60 | 90 | 120 | 200 | 300 | 500 | 800-1000 | ||

| Inventory | kg/batch | 0.5 | 5 | 10 | 15 | 30 | 60 | 90 | 120 | 200 | 300 | 500 | Design according to user requirements | |

| Fan power | kw | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 55 | ||

| Compressed air | pressure | Mpa | 0.6 | |||||||||||

| Consumption | m³/min | 0.45 | 0.6 | 0.6 | 0.6 | 0.6 | 0.9 | 1.1 | 1.3 | 1.8 | 2.4 | 3 | ||

| Steam | Pressure | Mpa | 0.4-0.6 | |||||||||||

| Consumption | Kg/h | 6KW | 9KW | 53 | 71 | 95 | 143 | 167 | 183 | 343 | 381 | 450 | ||

| Host size | H1(mm) | 2600 | 2600 | 2300 | 2450 | 2450 | 3050 | 3050 | 3050 | 3500 | 3700 | 4050 | ||

| H2(mm) | 250 | 320 | 340 | 490 | 540 | 590 | 690 | 790 | 890 | |||||

| H3(mm) | 2100 | 2250 | 2250 | 2850 | 2850 | 2850 | 3300 | 3500 | 3850 | |||||

| Ø1(mm) | 300 | 550 | 550 | 650 | 700 | 1000 | 1100 | 1200 | 1400 | 1600 | 1800 | |||

| Ø2(mm) | 150 | 180 | 180 | 250 | 250 | 280 | 280 | 280 | 280 | 315 | 355 | |||

| B1(mm) | 1550 | 1650 | 1010 | 1110 | 1160 | 1460 | 1560 | 1660 | 1860 | 2060 | 2260 | |||

| B2(mm) | 1460 | 1760 | 1860 | 2460 | 2660 | 2860 | 3260 | 3660 | 4060 | |||||

| L(mm) | 850 | 1100 | 1100 | 1250 | 1530 | 1530 | 1650 | 1650 | 1750 | 1850 | ||||